COERCITIVITY OF THE SAMPLE

Is the value of reverse magnetizing force required to wipe out the residual magnetism in the sample

Now H is further increased in the reversed direction until point d is reached where the sample is saturated in the revision direction ( ).

).

If the H is now reduced to zero, point e is reached and the sample again retain magnetic flux density ( )

)

The remaining part of the loop is obtained by increasing current to produce H in the original direction .

The hysteresis loop results became the domains do not become completely unaligned when H is made zero.

The area enclosed by the hysteresis loop represents loss in energy

This energy appears in the material as heat.

HYSTERESIS LOSS

This is the loss of energy in the form of heat when a ferromagnetic material is subjected to cycles of magnetization.

Hysteresis loss is present in all those electrical machines whose iron parts are subjected to cycles of magnetization.

The obvious effect of hysteresis loss is the rise in temperature of the machine.

HYSTERESIS LOOP

Is the loop traced by the resultant B-H curve when the Iron – cored toroid is subjected to a cycle of magnetization.

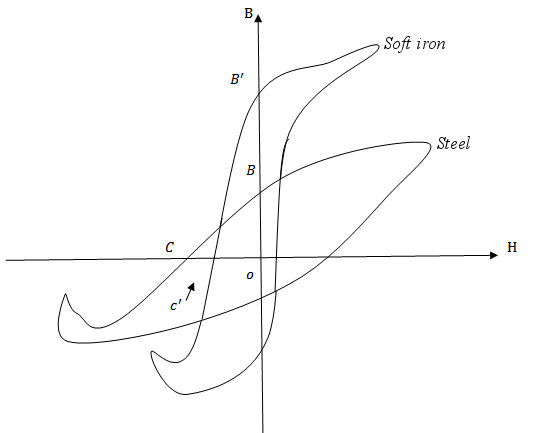

The shape and size of hysteresis loop largely depends upon the nature of the material

The choice of a ferromagnetic material per a particular application often depends upon the shape and size of the hysteresis loop

(i) The smaller the hysteresis loop area of a ferromagnetic material the smaller is the hysteresis loss

The hysteresis loop per silicon steel has a very small area.

For this reason, silicon steel is widely used per making transformer cores and rotating machines which are subjected to rapid reversals of magnetization

(ii) The hysteresis loop per hard steel indicates that this material has high retentivity and Coercivity.

Therefore hard steel is quite suitable for making permanent magnets.

But due to the large area of the loop there is a greater hysteresis loss

For this reason, hard steel is not suitable for the construction of electrical machines

(iii)The hysteresis loop for wrought iron shows that this material has fairly good residual magnetism and Coercivity.

Hence it is suitable for marking cores of electromagnets

APPLICATIONS OF FERROMAGNETIC MATERIALS

Ferromagnetic material (E.g. iron, steel nickel, cobalt etc) are widely used in a number of applications

The choice of ferromagnetic material for a particular for a particular application depends upon its magnetic properties such as

(i) Retentivity

(ii)Coercivity

(iii) Area of the hysteresis loop

Ferromagnetic materials are classified as being either

(i) Soft (soft iron)

(ii) Hard (steel)

Figure below shows the hysteresis loop for soft and hard ferromagnetic materials

The table below gives the magnetic properties of hard and soft ferromagnetic materials

|

Magnetic property |

Soft |

Hard |

| Hysteresis loop | narrow | Large area |

| Retentivity | High | High |

| Coercivity | low | high |

edu.uptymez.com

(i) PERMANENT MAGNETS

The permanent magnets are made for hard ferromagnetic materials (steel, cobalt, carbon steel)

Since these materials have high relativity the magnet is quite strong

Due to their high Coercivity, they are unlikely to be demagnetized by stray magnetic field

(ii) TEMPORARY MAGNETS / ELECTROMAGNETIC

The Electromagnets are made from soft ferromagnetic materials e.g. soft iron.

Since these materials have low coercively they can be easily demagnetized.

Due to high saturation flux density they make strong magnets

(iii) TRANSFORMER CORES

The transformer cores are made from soft ferromagnetic materials

When a transformer is in use, its core is taken through many cycles of magnetization

Energy is dissipated in the core in the form of heat during each cycle. The energy dissipated is known as hysteresis loss. And is proportional to the area of hysteresis loop

Since the soft Ferromagnetic materials have narrow hysteresis loop (smaller loop areas) they are used for making transformer cores.