It is obtained from 2 words

– Poly – many

– Merons- units

· Polymers are gigantic molecules which form chain of molecules.

·

A polymer is a giant chain like molecule obtained by intermolecular combination of large number of small molecules of the same or different types known as monomers.

E.g: Nylon 6,6

· Monomers are small molecules(simple molecules having low molecules) which capable of combining almost infinity together to form a polymers.

Structure of polymers

The primary structure of polymers is given by the types of monomers and their arrangement in molecules in the polymer.

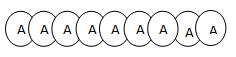

If the polymer is made up of one types of monomer, it is known as Homopolymer or simple polymer.

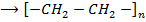

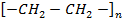

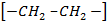

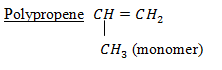

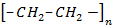

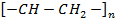

E.g:

i.

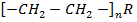

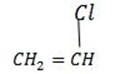

ii. PVC i.e

If the polymer is made up of two or more different types of monomers known as copolymer

There are 3 types of copolymer depending on order of polymer units

TYPES OF POLYMERS

- Synthetic Polymers.

- Natural / Synthetic rubber.

- Vulcanisation .

edu.uptymez.com

Examples of copolymer include:

(a) Nylon 6,6

(b) Polyester

Polymer can be classified into 2 classes on the basis of their structures

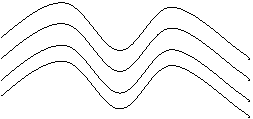

(a) Linear polymer

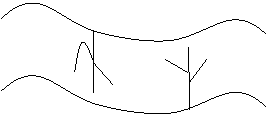

(b) Branched chain polymer

Linear chain polymer

Branched chain polymer

Properties:

i. Linear chain polymer have higher melting point and boiling point than branched polymers

Reason: – Van der Waal forces are stronger in the linear chain polymer.

ii. Linear polymer have higher density

iii. Linear polymer also have higher tensile strength

i)Classification based on molecular forces

There are 2 major classes

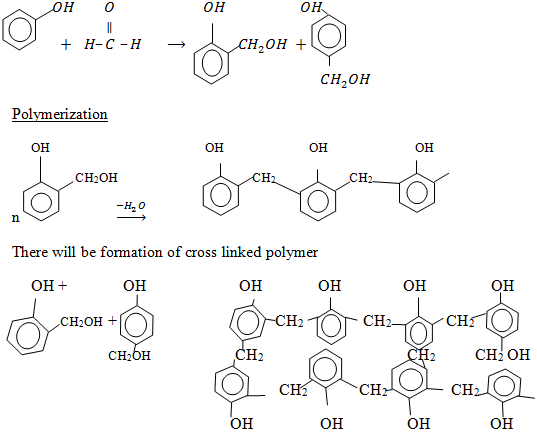

1. Thermosetting polymer

2. Thermoplastic polymer

THERMOSETTING POLYMER

– These are polymers which cannot be moulded on heating

– When heated they become hard.

Reason: – On heating they undergo further reaction which increases cross linked chain. They cannot be fused i.e infusible.

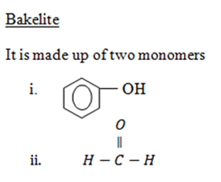

E.g: Bakelite

THERMOPLASTIC POLYMER

These are polymers which can be moulded on heating.

– They become soft when and when heated become stiff

E.g: PVC

They are linear structures with no cross linkage. Van der Waal will exist between molecules

ii)Classification based on the nature of polymer

There are 2 major classes

1. Natural

2. Artificial or synthetic polymer

Natural polymers

Example:

i. Cotton made up of cellulose, starch (made of glucose)

ii. Bamboo stick

iii. Paper

iv. Proteins

v. DNA, monomer nucleic acid

Artificial polymers

Example:

iii)Classification based on the mechanism of polymerization

There are 2 major classes of polymer

a. Addition polymer

b. Condensation polymer

A.

Addition polymerization

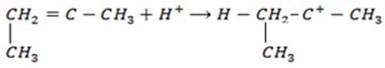

This is due to combination of unsaturated monomers (contain double or triple bond)

Ethene polyethene

Addition polymerization proceeds into 3 possible mechanisms

1. -Free radical polymerization

2. -Cationic polymerization

3. -Anionic polymerization

Free radical polymerization

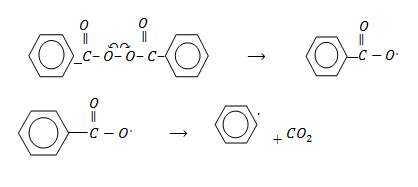

Free radical polymerization is one which the reaction are catalysed by free radical obtained by organic peroxide (R–O–O–R`)

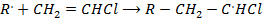

Step: 01 Chain initiation step

Step: 01 Chain initiation step

.

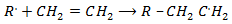

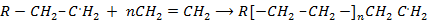

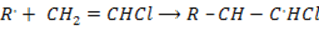

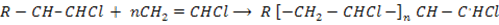

Step : 02 Chain propagation step

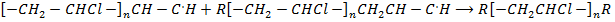

Step: 03 Chain termination step

The reaction stops when two free reactions combine or when the radicals undergo disproportionation

R

+ R

+ R

Example

Polymer

Chain initiation step .

Chain propagation step

Chain termination step

R–

Polymer

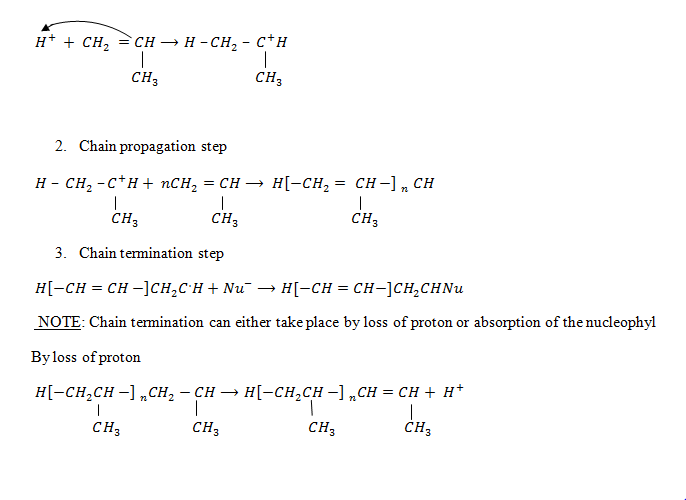

Other polymer can be made from

Cationic polymerization

In this polymerization the initiator is an electrophyl. The electrophyl adds to the alkene causing it to become a cation

Example of initiators:-

electrophiles H+, – NO2

i. Lewis acid e.g  ,

,  , H+

, H+

Mechanism

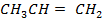

1. 1. Chain initiation step

Here we use a strong base to remove the hydrogen

Other monomers which can undergo Cationic polymerization include

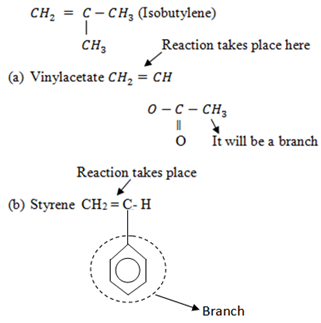

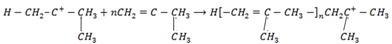

Using Isobutylene

1.

1. Chain initiation step

2.Chain propagation step

3.

3. Chain termination step

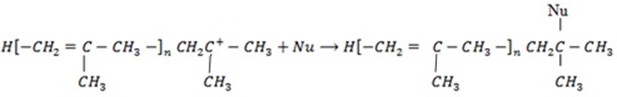

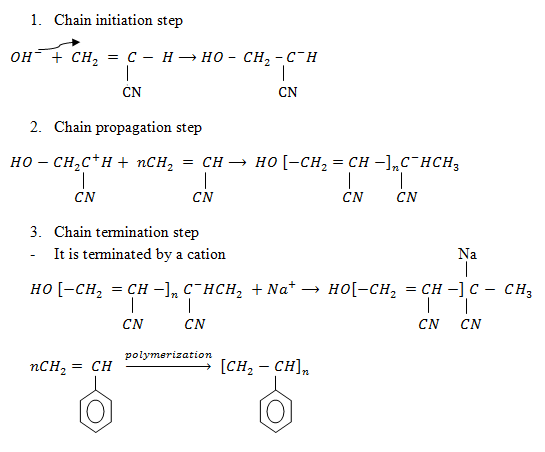

Anionic polymerization

Mechanism

Initiated by nucleophile that react with alkenes to form anionic propagating site

Example of nucleophile

NaNH2

Butyl lithium BuLi

R – O– (Alkoxide)

Grignard reagent

This reaction occur if the carbon is stabilized by a suitable electron withdrawing group

Mechanism

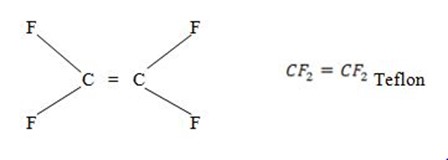

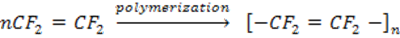

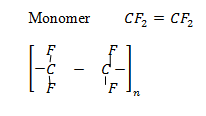

Polytetraloroethene

Uses of polymers :

Used in making pipes, bags, container and unbreakable bottles

Polyethene

Used in making pipes, containers, bottles, electrical insulation

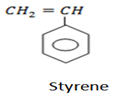

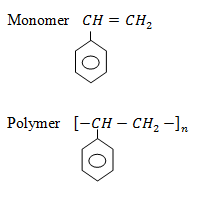

Styrene

USES:

– Household goods

– Electrical insulation

– Optical lenses

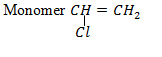

Polychloroethane

Typical chain section

USES;

– Cable insulation

– Pipes

– Hoses

– Fabrics

– Flooring

Polytetrafluoroethane

USES:

– -Surface coating of fans (non stick)

– -Pipes

– -Apparatus for chemical plants

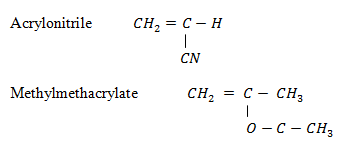

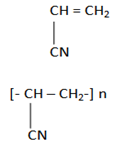

6. Polypropanonitrile

Monomer

Monomer

USES:

-Tertiles

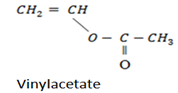

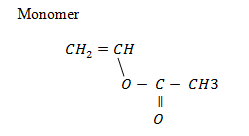

7.Polyethanylethanoate (vinyl acetate)

USES:

– -Paints

– -Adhesives

– -Water repellent coating

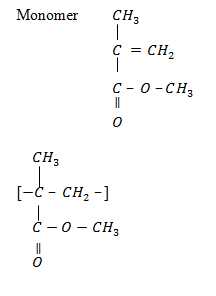

8.Perspex (polymethyl-2- methyl(propanoate)

USES:

– -Optical lenses

– -Glasses

– -Used as glue and paint

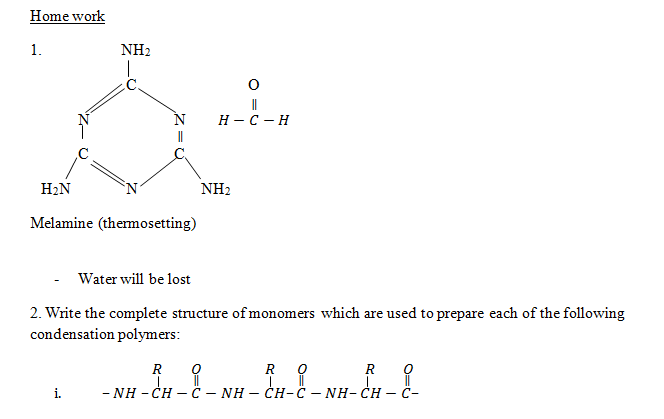

CONDESATION POLYMERIZATION

It takes place through condensation reaction between two bifunctional or trifunctional monomers with simultaneous loss of small molecules such as H2O, HCl, NH3 etc.

Example:

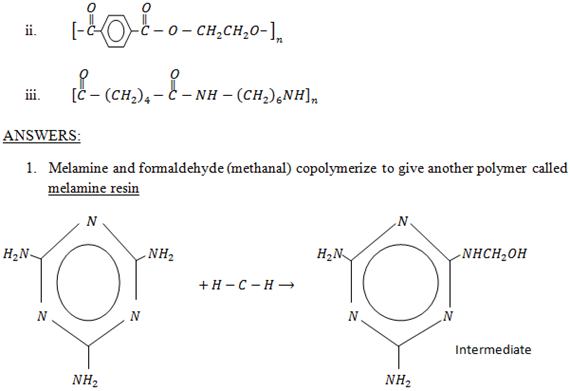

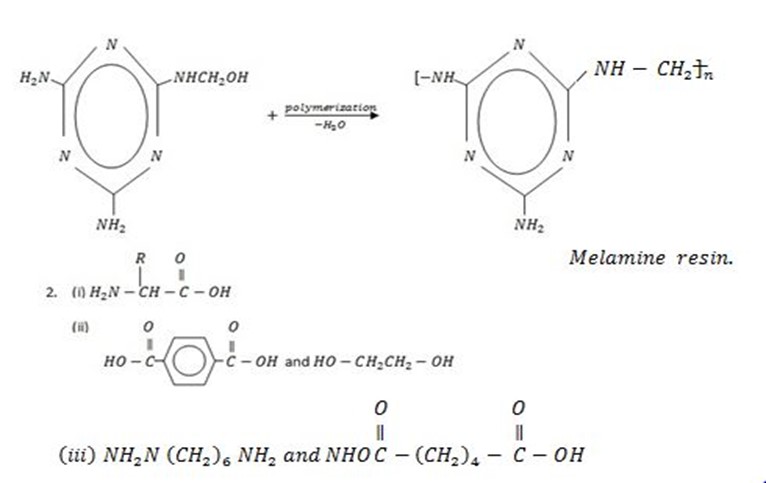

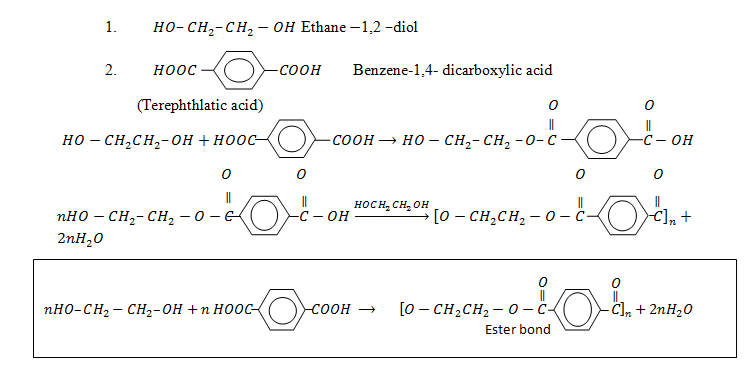

i. Polyesters

ii. Polyamides or polypeptides

iii. Terylene

It is made up of two monomers

Polyester e.g Terylene.

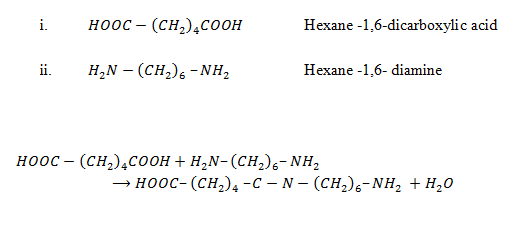

Polyamides e.g Nylon 6, 6 (polyamide)

It is made up of two monomers

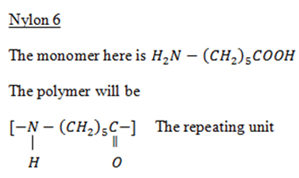

Nylon 6,6